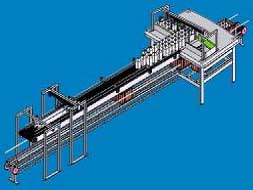

New Daytona Dynamic High Speed Packer

Overview

With fillers getting faster and faster, R & R Performance Engineering Ltd are developing the Daytona Dynamic High Speed Packer. Using a high speed multiple lane product diverter, product is arranged into the required rows for packing. Once the product fills the pack area a servo drive system transfers the pack and a crate across to the pack zone. As the product drops into the crate another pack and crate is being set into a second carriage ready for packing. The servo system returns, moving the second pack and crate into the second pack zone. The internal crate system side shifts the crate into place for packing from a single crate infeed conveyor. Once the crate is packed it is shifted forward then returned to a single exit conveyor.

The unique method of side transferring the product allows one crate to be packed while the product transfer system pre accumulates the next pack ready for packing. An innovative internal crate delivery system allows crate delivery and exit via a single conveyor system. A high speed multiple lane product diverter pre accumulates bottles into their appropriate pack sizes. Allen Bradley touch screen interface gives the operator the run status of the packer at all times.

Features

- Multiple bottle size configuration

- Easy set up for different bottles sizes

- Automated operation

- Touch screen operation

- Flexible conveyor system

- Data acquisition capabilities (fault analysis and machine status)

- Plug and play sensors

- Seamless factory integration

General Specifications |

|

| Pneumatics: | Festo |

| PLC and Interface: | Allen Bradley |

| Sensors: | ifm efector |

| Speed: | Up to 30 crates per minute |

| Voltage: | 230 volt/415 volt 50/hz |

| Amps: | 20 amp |

| Weight: | 500kg (approximately) |

| Air consumption: | 200 litres per minute @ 600 KPA maximum pressures |

| Maximum air flow: | 300 litres per minute |

| Dimensions: | 5545mm long including diverter, 2000mm wide |